The implosion of OceanGate’s submersible, Titan, on June 18 has faced scrutiny for the use of carbon fiber in its design. Engineering SOURCE at Colorado State University sat down with mechanical engineering Professor Mostafa Yourdkhani, who specializes in composite materials, to answer some common questions surrounding carbon fiber composites. Answers have been summarized and shortened for clarity.

Yourdkhani’s research program at CSU has been focused on 3-D printing of composite materials, including carbon fiber. He and his research team are working on reducing the cost, time and energy that is required for production of these complex materials and structures.

What are carbon fiber composites? How are they made?

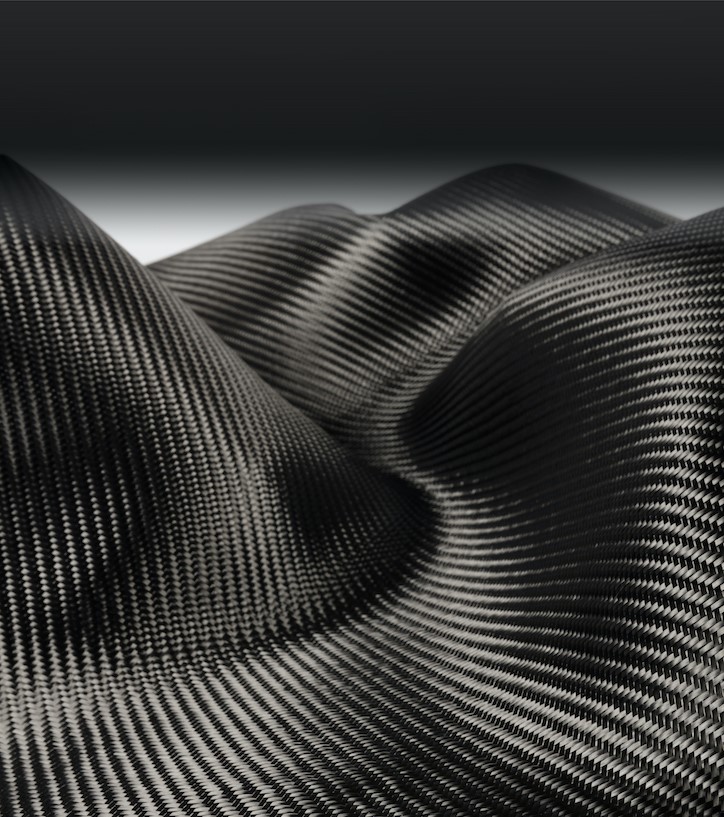

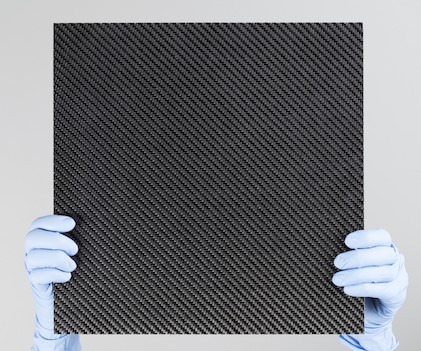

Composites are a “material system” that is made up of two or more materials. An example of this is concrete. Concrete is made up of cement, sand, and other materials. Rebar is added to make a strong end product. This same concept applies to composites. Carbon fiber by itself is tiny fibers, like the fabric from textiles but almost 10 times smaller in diameter than human hair, Yourdkhani said. Carbon fiber is incredibly strong under tension. When you pull on the fibers, they’re strong, but if you compress or compact them, there’s no resistance. A polymer, typically a resin like epoxy, is added to the spaces between the threads of the carbon fiber to increase resistance when compacted. Most of the time, the polymer must be solidified or “cured” through heating the material. This two-material system works together as a whole to create a very strong material that is resistant to tension, compression, and bending if properly designed and manufactured.

Why is using carbon fiber composite advantageous? What kinds of things is the material used for?

The combination of carbon fiber and polymers results in a material that is much more lightweight than metals like steel and aluminum while giving you a material that’s stronger than aluminum and steel. Another advantage of carbon fiber composites is that, unlike metals, this material does not corrode, Yourdkhani said.

Carbon fiber composites are great for a variety of applications demanding a high-performance materials. Airplanes are a great example of material that must be strong and lightweight. Carbon fiber composites are used in aerospace and space applications, such as space crafts or airplanes, infrastructure such as bridges, the energy sector in wind turbine blades, as well as more “everyday” uses such as tennis rackets, skis, racecars, prosthetics, and bicycles.

Not all carbon fiber composites are created equal. Depending on applications, a variety of fibers and polymers can be used. The kind of materials used in airplanes and space shuttles will use a more “pure,” higher quality (and expensive) version of carbon fiber and resin than you’ll find in a tennis racket or a ski.

OceanGate’s submersible, Titan, received criticism for the use of carbon fiber composites in its design. What are the limitations of composites?

Composites are a lightweight, corrosion-resistant, and thermally stable material, but like any other materials, they have challenges, and if those challenges are not considered, they can lead to catastrophic failure—whether that’s in bike, tennis racket, or in a submersible. Manufacturing and inspection processes are crucial to avoiding material failures, Yourdkhani said.

“One challenge is that if there are defects in the composite, such as air bubbles or gaps that are left around the carbon fibers, that becomes a weak point,” Yourdkhani said. “If weight or pressure is applied, there is a very high chance that your structure will start to fail. Another challenge with this is that defects occur inside the material that are not visible to the naked eye.” So how can we identify these defects? There are techniques for this that are a part of a tedious process, which is another reason why producing carbon fiber composites can be so expensive. The idea is similar to the imaging techniques used in the medical field. The most common inspection technique is the use of ultrasound to see inside the material and identify inconsistencies. There are ultrasound machines that scan the surface of a composite structure and detects potential defects. Since every part of a structure should be inspected locally, the process becomes slow and expensive to run but such inspections are vital to assure the quality of produced parts and are standard in the industry.

Another challenge is something called “fatigue.” Fatigue is when material undergoes “loading” and “unloading,” or the process of applying and removing pressure, such as when a submersible goes down into the ocean and comes back up to the surface. If there are defects present, those defects will start to grow. An inspection needs to be done after each process of unloading and loading to ensure that no defect or damage has progressed inside the structure.

“When a submersible is going underwater to significant depths, the pressure that vessel is experiencing is much higher than an airplane in the air, so these challenges are exponentially increased,” Yourdkhani said. “Obviously at this time the cause of failure is not known, all we can do is speculate, but composites are actually quite safe if they are well designed, manufactured, and tested.”