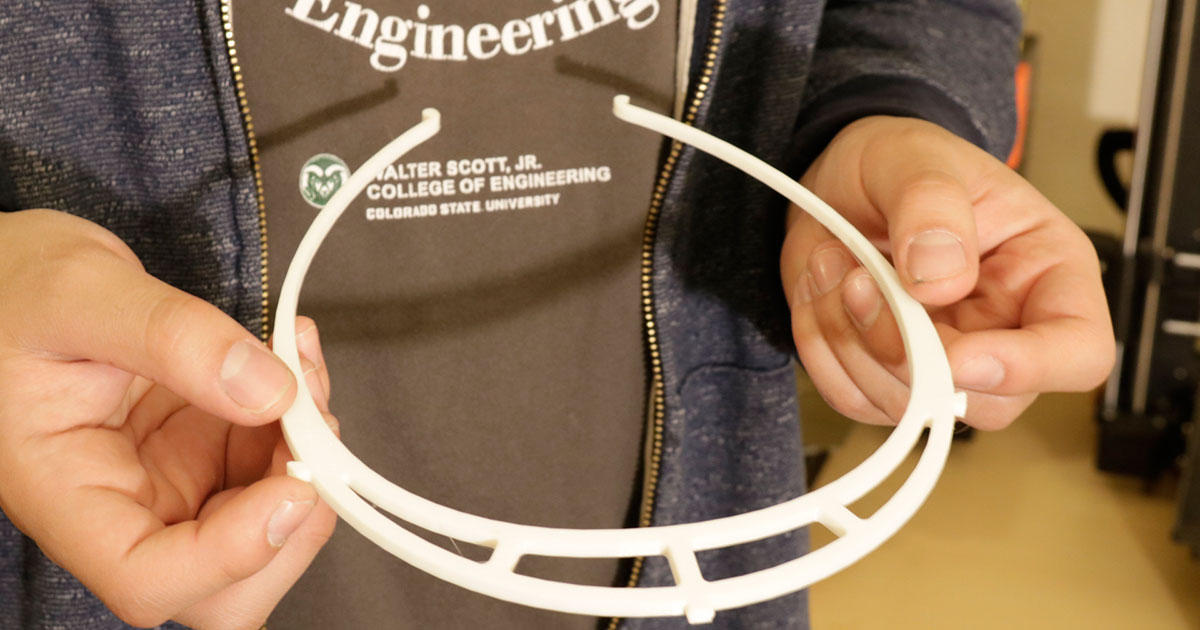

Jeremy Rodriquez holds a 3D-printed face shield halo.

As in other states, the coronavirus pandemic is forcing Colorado hospitals to face the possibility of running out of beds for patients and personal protective equipment for workers. Across the state – really, the world – people are stepping up to ask, what can we do to help?

That includes the Colorado State University community. Over the last few weeks, a loose consortium of faculty and students have joined a centralized effort to make as many medical supplies as they can for the people who need them.

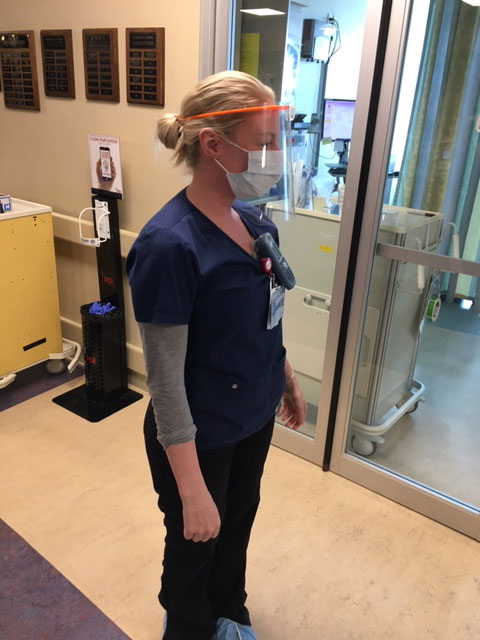

CSU’s Idea-2-Product 3D printing lab, along with faculty who have 3D printers in their own labs, have been part of a statewide initiative to ramp up production of medical face shields. These face shields are wide plastic coverings, held to the forehead by a thin plastic band called a halo, that offer further protection for medical personnel beyond masks and safety goggles. A Greeley-based medical equipment company, Genesis Plastics Technologies, has been called upon by Gov. Jared Polis’ Innovation Response Team Task Force to expedite the manufacture of about 50,000 such face shield kits per day using injection molding, which requires the company to redesign their production lines.

Alan Rudolph, CSU’s vice president for research, serves on the governor’s task force and has designated Assistant Vice President Ellen Fisher as a key point of contact between the university and the state for PPE testing. That includes the community efforts behind face shield manufacturing that have taken place over the last several weeks.

“Our university has so many dedicated people with the expertise, knowledge and equipment that, if needed, can be used to serve the people of Colorado,” Fisher said. “That’s part of our mission, and we stand ready to continue providing every resource we possibly can to help during this pandemic.”

Printing around the clock

A local doctor wearing one of the face shields CSU helped make.

Until Genesis’ production lines are at full capacity, the halo components of the shields need to be 3D printed, which is a much slower process. The 3D printers on campus have been working around the clock – many of them from the bedrooms and apartments of CSU students – to join many others around the state creating the halos and delivering them to Genesis Plastics to contribute to supply stockpiles. Official safety and fit testing of the face shield design and materials has taken place at the University of Colorado Anschutz Medical Campus, as designated by the state.

David Prawel, associate research professor in mechanical engineering and director of the Idea-2-Product lab, is leading CSU’s effort to print and supply as many face shield halos as possible. Designs for the halos were centrally vetted and approved by the Governor’s Task Force and Genesis Plastics.

“One printer can do about 12 to 14 a day,” Prawel said. With six printers at their disposal, at full capacity he and the lab can produce about 80 halos a day.

“We have the capability, and there is a need,” Prawel said. “And that’s what we do.”

Others who have offered printers include Christian Puttlitz, head of the Department of Mechanical Engineering, and Jay Ham, professor in the Department of Soil and Crop Sciences, each of whom have 3D printers in their labs that normally support their individual research programs.

“These are efforts being duplicated by many, many mechanical engineering departments across the country,” Puttlitz said. “It’s an opportunity to contribute in a safe way, and hopefully keep our healthcare providers safe – that’s really the goal.”

Working from home

Jeremy Rodriquez is an undergraduate electrical engineering student who is also an experienced technician in the Idea-2-Product lab. Just before Polis’ stay-at-home order took effect in March, he worked with Prawel to take two printers to his apartment so he could continue printing the halos away from campus. Puttlitz’ graduate student Jason Kuiper did the same and has been producing about 20 halos a day using one of the lab’s printers.

After Spring Break, Rodriquez was moving to a new house in Fort Collins, starting online classes, and setting up the home printing operation. He has been simultaneously operating the two CSU printers, as well as his personal one, and has made about 50 halos. He’s disinfecting and bagging them individually before another student from the lab picks them up and takes them to Genesis Plastics.

“I’ve always been really big into helping people. Any sort of beacon of light can make a big difference,” Rodriquez said. He was especially interested in using his skills for the face shield project, he said, because one of his family members recently died of COVID-19.

“I hope we can give people assurance that everything is going to be OK, that people are helping,” he said.