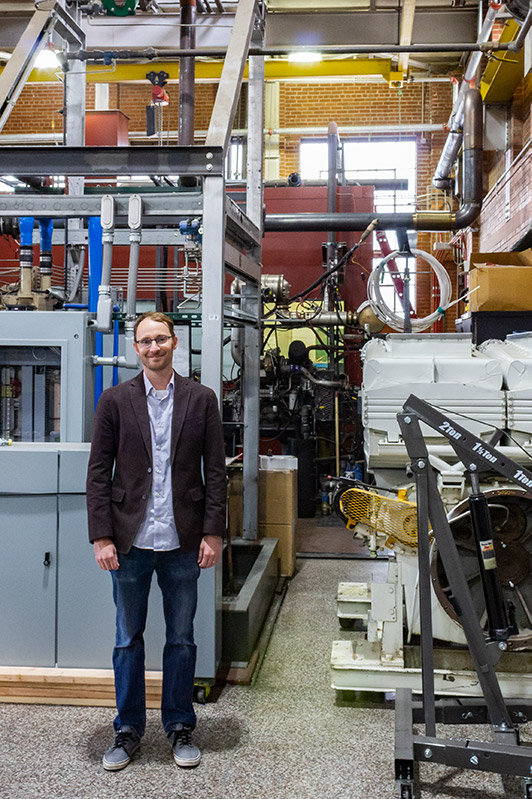

Mechanical engineering assistant professor Bret Windom seeks to identify biomass-based molecules to mix with diesel fuel, to reduce soot in engines and improve the engine’s performance.

Seems simple enough: Work through models to isolate the best molecular structures, then blend the right chemicals together, carry out a few experiments, and choose the correct mixture.

Not so fast.

Since the molecules originate from plants, Windom needs an investigator with specific chemical and biological engineering expertise. He also needs another mechanical engineer, with expertise different from his own, in high temperature and pressure combustion experimentation.

Some expertise comes from other researchers at CSU, and some technologies are only available at other research institutions like Yale University or the University of Colorado. That includes researchers who have extensive knowledge of soot formation, and others who can chemically “freeze“ molecules before they react with one another to determine the chemical pathways responsible for ignition and pollution formation.

Different molecules are sent through every step in the process until the best choice is found. Even if all of the research needs are acquired and a perfect molecule established, a significant question remains: is the final solution even economically or environmentally feasible?

Working with experts across departments, colleges, and institutions is not just about finding a molecule or two. Interdisciplinary collaboration can help answer some of the most complex scientific questions of our time.

Balancing efficiency and health concerns

The three-year, $2 million U.S. Department of Energy (DOE) grant provides funds to research production of better bio-blendstocks—biomass-derived renewable fuels mixed with conventional fuels—that can reduce soot and other criteria emissions from high-efficiency diesel engines, without needing expensive exhaust aftertreatments.

Various fuel mixtures have advantages and disadvantages. On one end of the spectrum, conventional diesel fuel creates an enormous amount of energy when combusted, but also generates a great deal of soot and nitrous oxide emissions.

At the other end, biomass-derived poly(oxymethylene) dimethyl ethers (POM-DME) emit half of the soot. But those ethers have very poor heating values, and have issues with cold flow performance and water solubility, limiting how useful they are as a fuel.

To address environmental concerns and create a viable bio-blendstock, the team will focus on different variants of poly(oxymethylene) ether (POM-E) molecules, where the carbon methyl groups from POM-DMEs are lengthened. Through a step-by-step process, the goal is to identify which POM-E molecules offer efficient combustion without increasing health concerns.

“Efficiency wasn’t a concern when we started burning petroleum fuels because it had so much energy, and we weren’t fully aware of the health impacts,” said co-principal investigator Windom. “Now we’re trying to find the carbon-neutral sweet spot where we’re balancing heating value, sooting, and other important combustion properties required for high efficiency energy conversion.”

A specific type of chemical and biological expertise

When the grant was approved, DOE required that the initial testing be done with molecules specifically created from biological components. Having the right chemical engineer, with a specific type of expertise, made that adjustment much easier.

“When you are synthesizing molecules directly from biomass, there can be other chemicals present that might cause a problem down the line,” said Ken Reardon, professor and Jud and Pat Harper Chair of Chemical and Biological Engineering. “They asked us to test at least one batch starting with material we absolutely knew came from plants.”

Reardon’s knowledge of generating molecules from biomass brings to the table an important factor in the team’s success. But often the labels and terms for types of engineering, such as “chemical engineer,” are too broad to really explain the diverse nature of expertise within the field.

“My colleagues in my department are doing things I couldn’t begin to do, yet we’re all under the same label,” said Reardon, co-principal investigator on the project. “And a lot of us in the college do things that wouldn’t classically be considered chemical engineering.”

After creating the initial molecule, the process goes back and forth between burning fuels, quantum chemistry tests, chemically freezing molecules in a reactor, and testing combustion at high pressure. It is the place where having multiple disciplines comes to fruition.

Of flame, quantum chemistry, and freezing molecules

Windom experiments with different molecules, mixed with diesel fuel, to see how they impact flame formation and emissions. Altering the type of molecules and their concentrations changes how flames look and how efficiently they burn.

Using the photos above, Windom explained how different fuel molecules affect the intensity and color of the flame throughout the process. “The difference in the intensity and color of these flames is the soot radiating. The brighter flames have more soot and that is what is causing the difference in luminosity.”

After a molecule is tested with flame, co-principal investigators Charles McEnally and Lisa Pfefferle at Yale University determine the levels of sooting produced. Using small amounts of the molecule, investigators can examine the flame’s intensity for how much soot is released.

Back at CSU, the molecule is tested through a combustion system created by mechanical engineering professor and Associate Dean Anthony Marchese. The device can simulate the high temperature and pressure of an engine, allowing for the measurement of the molecule’s ignition delays.

Marchese, a co-principal investigator, said he has been a mentor to Windom, and is excited to see the project evolving. “It is an honor and privilege of mine to be part of this strong multidisciplinary, multi-institution team that Bret has assembled,” said Marchese.

At the University of Colorado, co-principal investigator Nicole Labbe, an expert in chemical mechanism development, then performs calculations and experiments on the molecule to determine the rate of reactions. Using a small amount of fuel in a unique reactor, she can react, then chemically “freeze,” the molecules in a vacuum at the correct moment to analyze the composition of the fuel.

“Normally if you’re trying to measure the composition of a reacting gas, the sampled molecules will react with each other before you can detect them,” said Windom. “Through this reactor the molecules can’t see each other and aren’t reacting, allowing us to analyze the composition.”

Even knowing which molecules would work best, through both theory and experimentation, only matters in the long run if producing the solution is economically and environmentally sustainable.

Is making the molecule even viable?

At each step of the process, considerations are not only about how well a molecule combusts in the mixture, but if it is something that can be created safely and economically at a larger scale. Examining the life cycle of an alternative fuel is where mechanical engineering associate professor and Rockwell-Anderson Professor Jason Quinn steps in.

“I think my work’s the most exciting,” said co-principal investigator Quinn. “If you told me a year ago that I’d have access to fundamental combustion science, I would have said you’re crazy.”

“All of a sudden you’re going down a path you never would have on your own.”

Quinn’s role on the project is to determine the life cycle of each molecule. From the molecule’s creation to its final burning, Quinn determines the economic viability and, more importantly, environmental impact of these alternative fuels. He examines how production of the bio-blendstock would work at a commercial scale, and considers each molecule throughout the iterative process.

Working together adds to scientific knowledge

The iterative process not only helps evaluate how the particular molecules react as a bio-blendstock, the project adds to our overall scientific knowledge. Whether a particular molecule is viable or not, the resulting information builds on other projects and ideas.

Generating new paths to knowledge is something the interdisciplinary nature of the project feeds into naturally. With so many unique voices on the project, new ideas can evolve which add to the collective knowledge.

“It’s really a catalyst, having different people in the room thinking of different ways that you never would have approached it from,” said Quinn. “All of a sudden you’re going down a path you never would have on your own.”