Colorado State University is known as a hub for innovation and research; the University generated almost $400 million in research expenditures in the 2018 fiscal year.

That includes all the money spent outside of the University for fabrication and prototype development for new ideas, upgrading essential parts, and supporting ongoing research.

One engineer at the CSU Energy Institute has been working to keep those outsourced dollars on campus. John Mizia, director of the Advanced Biomass Combustion Lab, has developed a prototyping and engineering center at the Powerhouse Energy Campus.

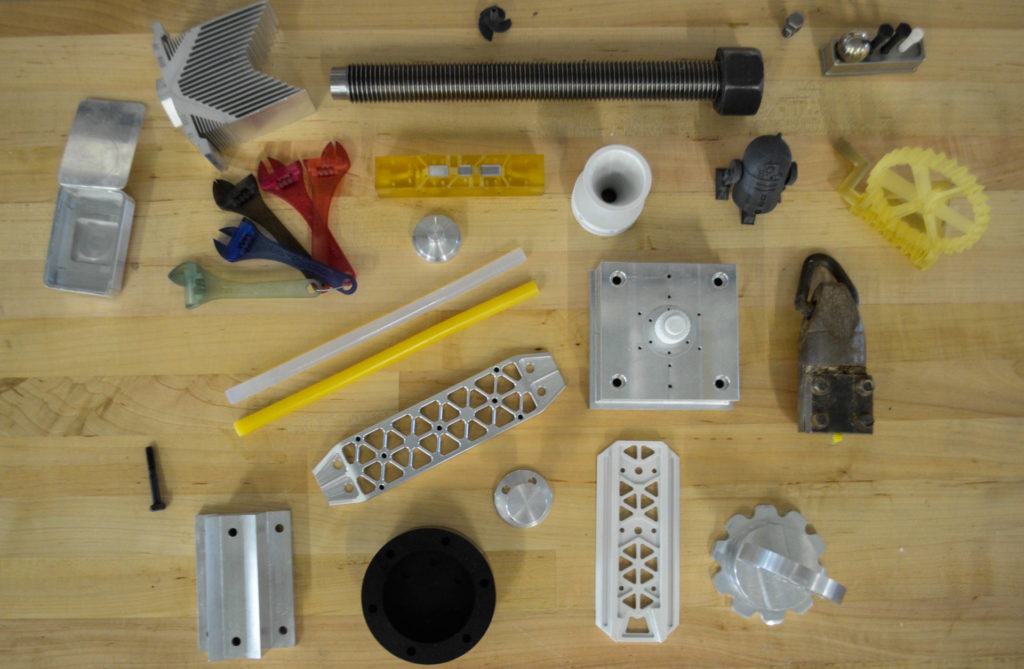

The Rapid Prototyping and Applied Engineering Lab has begun serving the CSU research community under the direction of Mizia and Kirk Evans, director of engineering at the Energy Institute. The RPL is a fabrication and engineering consultant group that provides support for other researchers as an official University Service Center as well as providing hands-on opportunities to students.

The lab’s mission is to accelerate innovation by providing the research community with engineering expertise in a world-class facility focused on rapid prototyping, applied engineering, and data acquisition.

World-class engineering services in-house

The lab offers expertise and advice on broad, applied engineering topics, as well as manufacturing of specific equipment and widgets on a per-project basis for any type of research.

“We’re talking about electrical engineering, agricultural engineering, the physics department; really, any CSU department conducting research could benefit from this internal lab,” said Mizia. “If they need unique manufacturing, advice, or connections, we can provide it. We have streamlined access to the necessary machines to provide cost-competitive rapid turnaround of high-quality engineering.”

The CSU Energy Institute has always honored hands-on involvement in research product development, which is reflected in the mission of this lab and its corresponding model of efficient, practical approaches to problems.

“The lab becomes even more valuable to departments outside of engineering; they might need a specific part to conduct their research but might not have something that will meet their needs,” said Evans. “That’s where we can step in and add a lot of value.”

The root of the idea

In the 1990s and early 2000s, the Engines and Energy Conversion Lab, housed at what is now the CSU Powerhouse Energy Campus, was a hub for hands-on problem solving and in-house manufacturing.

Mizia recalled those days as a graduate student himself. “If you needed a certain piece for your research and you didn’t have it, you had to figure out how to make it.”

As research at the Energy Institute expanded over the decades, there was an increase in demand for specialized parts and equipment. The engines lab could no longer satisfy these requests, and so that need was filled by outside vendors.

After earning his degree, Mizia spent a decade in aerospace designing propulsion system hardware for the Atlas V Launch Vehicle and overseeing precision manufacturing, where the margin for error was non-existent, the timelines were tight, and the product had to achieve stellar performance. Mizia brought this experience back to CSU and the Rapid Prototyping Lab.

“If we can provide world-class manufacturing, systems engineering, and data acquisition services internally, then we seamlessly integrate prototyping and manufacturing into the broader CSU research ecosystem,” he explained.

Accelerating innovation

The RPL received its first invoice in March, and since early June has completed over 30 projects ranging from magnetic field chambers to biomass combustors. Some additional examples of RPL’s work can be found on the lab’s website.

“If someone doesn’t know how to get something done, we are a great place to come and ask: ‘how can we do this?’” Mizia said. “And if we can’t, we certainly know people who can. Really, the sky’s the limit.”

Whatever problems the CSU research community needs help solving, Mizia and Evans are ready to tackle them. “Cross-disciplinary collaboration on research just elevates the game,” said Evans.

From engineering parts for smaller scale projects and turnkey style projects involving data acquisition to custom design and implementation, the RPL supports faculty and student research. “The simple truth of the matter is that, in research, sometimes the hardware you need to do that research doesn’t exist yet,” Evans explained.

Mizia and Evans are excited to be able to offer the lab’s services to the University as a whole and to add extra vitality to others’ research.

“The Energy Institute has always had a really strong reputation of being able to implement things quickly and from the ground up,” Evans added.

To submit a project request or get in contact with the RPL visit https://r3d3.colostate.edu/ or email John.Mizia@colostate.edu.