Until now, beyond 3D printing of polymers and ceramics, CSU has depended heavily on external collaboration for metal additive manufacturing capabilities. A 3D metal printer donation from Lockheed Martin – valued at about $700,000 – changes that.

The printer aims to accelerate innovation and economic development in the Department of Mechanical Engineering and throughout the CSU community and western region, helping prepare researchers and students for the latest technological advances in 3D printing. It will also elevate teaching resources, arriving to the department with new aerospace engineering and advanced manufacturing programs.

“Lockheed Martin is proud to strengthen our existing collaborative relationship with CSU through this gift, in tandem with our support of the Walter Scott Jr. College of Engineering” said Kristi Farley, Vice President of Spacecraft and Missile Engineering at Lockheed Martin. “We are excited that this gift will help further elevate the great engineering research and education happening at CSU and serve as a valuable resource for students who will go on to be the next generation of best-in-class STEM professionals.”

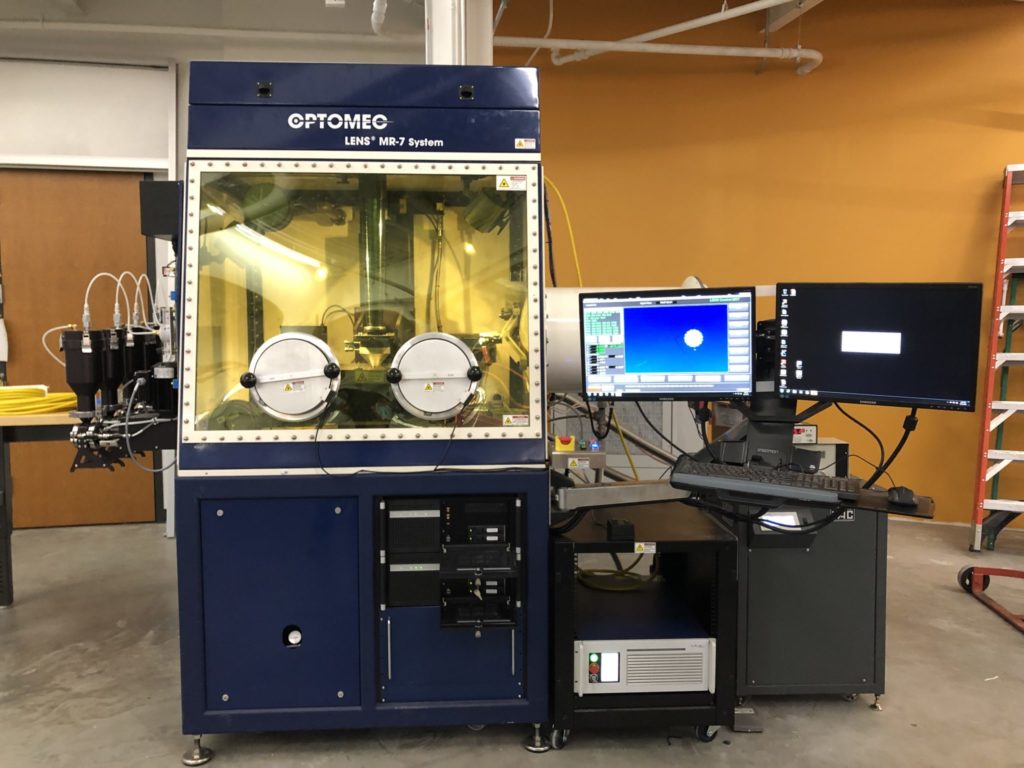

The printer, an Optomec Laser Engineered Net Shaping LENS System, utilizes a powder-fed additive manufacturing technology called directed energy deposition (DED). The technology can make complex objects in some of the most important, high-value metals including titanium alloys, stainless steel, aluminum, and nickel alloys such as Inconel, as well as ceramics like zirconia and alumina.

Compared to other technologies such as powder bed fusion systems, the DED printer has the unique capability to repair and rebuild damaged components. It can also enable the use of recycled metal machining waste as feedstock powder for sustainable material use – a pocketbook- and planet-friendlier alternative to traditional processing techniques.

The future of sustainable manufacturing

Additive manufacturing, commonly known as 3D printing, plays a key role in global product development and innovation. But the cost- and carbon-laden processing techniques of the past must evolve to meet climate and financial demands experienced by businesses.

Directed energy deposition from the LENS system could help.

“Laser DED allows us to reduce the material and energy consumption for making parts with 3D complex shapes, avoid or reduce the use of toxic cleaning chemicals that are heavily used in traditional manufacturing technologies, and repair many engineering components rather than throwing them away to the waste stream,” said Assistant Professor of Mechanical Engineering Kaka Ma, whose team will use the printer for research on advanced manufacturing of metals and ceramics. “It brings in a great benefit to the health of our environment and the whole planet.”

Aerospace manufacturers use the technology to produce structural parts for satellites and military aircraft. Numerous other industries, such as automotive, heavy equipment, mining and marine are already taking advantage of its benefits. Commercial aircraft may be next.

New opportunities for mechanical engineering

CSU’s Department of Mechanical Engineering plans to use the equipment in a way that integrates research, education, and outreach.

Possible research directions are focused on expanding the knowledge of how to use additive manufacturing technologies. This includes design and 3D printing of functionally graded material properties, custom metal alloys, and metal-ceramic composites, in-situ process monitoring and machine learning for part quality improvement, aerospace-related hybrid materials fabrication and repair, repair and refurbishment of metal components, and reducing environmental impacts of metal additive manufacturing.

In mechanical engineering classrooms, related curricula will be enriched significantly by including demonstrations of the system, and senior design project options will expand. The system will be a valuable addition to new technical electives currently in development for the department’s new aerospace engineering and advanced manufacturing programs.

Outreach activities may include inviting local middle and high school students for lab tours and demonstrations of the system to invoke early interest in STEM for long-term workforce development.

CSU also plans to provide access to the equipment. Industrial and academic researchers on the lookout for innovative and cost-effective production opportunities can establish use agreements with the university to use the technology.

“Access to a LENS printer is a rare opportunity. The ability to create fully dense complex metal parts in any material, or in custom materials, is unique in our multi-state region” said David Prawel, associate research professor in mechanical engineering. “This technology could deploy into products and innovations unimaginable today.”