It’s the bottom of the ninth. As the ball leaves the pitcher’s fingers, a shot of pain radiates down their shoulder accompanied by a loud “SNAP.” It’s a baseball player’s worst nightmare: a rotator cuff injury.

New technology developed at Colorado State University could speed up the healing process for this common injury.

Kirk McGilvray, associate director of the Orthopaedic Bioengineering Research Laboratory, is leading a research group set out to improve the healing process of rotator cuff injuries with the help of a 3-D printed implant.

Rotator cuff injuries are not unique to athletes—they can happen because of trauma or disease, especially with age. The rotator cuff contains five major attachment points that connect your arm to your shoulder. Typically the supraspinatus tendon, or the ligament that allows you to raise your hand over your head, is often the one that gets injured, McGilvray said.

The common healing process for a rotator cuff injury involves either physical therapy or surgery—and these don’t result in a guaranteed fix. “Even though there’s a lot of advancement in the field, there’s still a high rate of retear after surgical intervention,” said McGilvray.

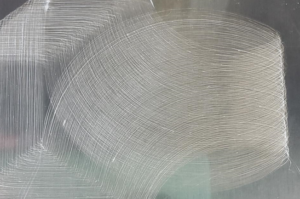

McGilvray’s research team is working to develop a scaffold, or a 3-D printed structure, containing a novel biomaterial that considers the mechanical environment of the shoulder and rotator cuff, as well as the immune response of the body.

This “instructive scaffold,” as his research team calls it, will aid rotator cuff healing in a two-step process. First, the scaffold will release a molecule which will attract the required cells for tendon and tissue repair. Then, after a certain amount of time has passed, a second molecule will be released, triggering an anti-inflammatory reaction that will help stimulate a healing response and build tissue.

Working with McGilvray are researchers from the Department of Clinical Sciences, Dr. Steven Dow and Dr. Lynn Pezzanite.

“As mechanical engineers, we’re really good at material development and 3-D printing, but our friends in clinical sciences help us understand the immunological response. So, by working together, our goal is to control the body’s response and form tissue between the bone and tendon all while improving clinical outcomes,” said McGilvray.

The technology could be a game changer for all kinds of tissue healing.

“Once we crack the door open of how to improve wound healing, we can start applying this technology to other places, like in the Achilles tendon or the stomach” said McGilvray. “The goal is not only to use this for humans, but also for veterinary medicine. If it can help a person, it can help an animal, like a dog or cat—we all have the same problems such as tearing soft tissues and breaking bones.”

McGilvray’s project is one of three Walter Scott, Jr. College of Engineering research projects to receive funding from Scott High-Impact Research grants in 2022-2023. The funds are the first of a multi-year commitment from the Scott Foundation to address some of the world’s greatest engineering challenges.