Soon after COVID-19 became a pandemic in 2020, Colorado State University life science researchers sprang into action, applying decades of microbiology, immunology and infectious disease expertise toward development of a vaccine candidate that could work against the new coronavirus.

Two years later, CSU’s research into vaccines for all kinds of diseases – not just COVID-19 – continues to thrive. That’s due in part to a one-of-a-kind vaccine-manufacturing and testing device that was designed and prototyped by CSU engineers, an idea conceived during those early, frenetic days of the pandemic. Now, this custom-built high-intensity flow-through photochemical reactor, called the “VacciRAPTOR,” is being integrated into the university’s wider coronavirus and other research efforts, as it can be used to inactivate many types of viruses and pathogens.

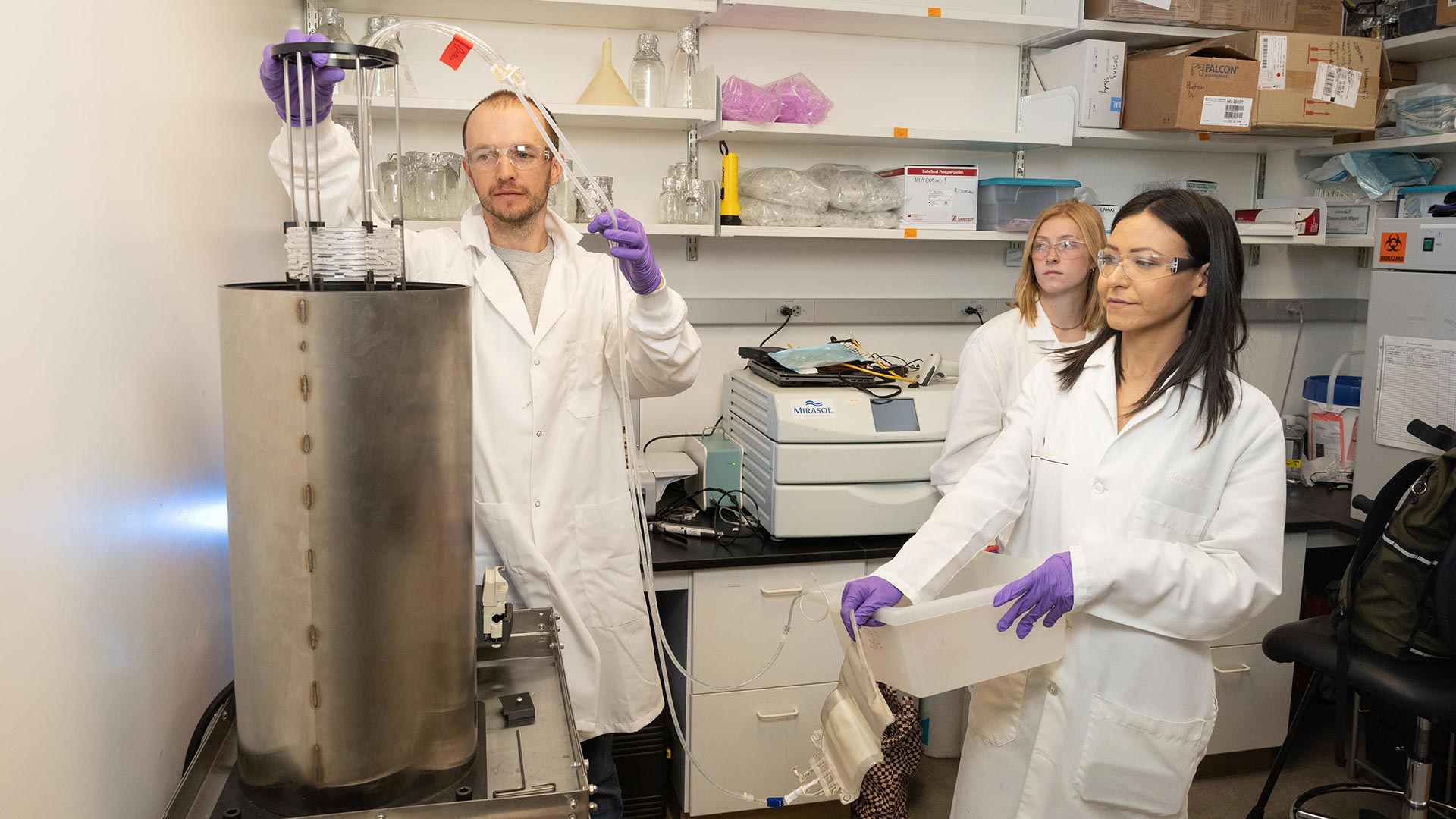

The VacciRAPTOR was built by a team of engineers at the Energy Institute’s Rapid Prototyping Lab led by senior research associate John Mizia. The lab’s principal engineer Matt Willman led device design, and master’s student Andrew Andraski is leading characterization and testing. The engineers collaborated on the project with the vaccine research team led by Raymond Goodrich, executive director of the Infectious Disease Research Center, and professor in the Department of Microbiology, Immunology and Pathology.

After two years of prototyping, the VacciRAPTOR recently made its way from the Powerhouse Energy Campus to the infectious disease research laboratories on the Foothills Campus. Now, it is allowing vaccines for numerous diseases to be made and tested many times more quickly and efficiently than previous systems, carving a smoother and faster path toward clinical trials.

Rapid development of a coronavirus vaccine

Early in the pandemic, Goodrich and colleagues started testing whether an existing pathogen-inactivation technology that combines the vitamin riboflavin and ultraviolet light could be used to develop a coronavirus vaccine. Their goal was to create a vaccine based on an inactivated, intact virus, which would stimulate the immune response but not cause disease in the patient.

The technology is based on two decades of work by Goodrich and colleagues who’d previously invented a pathogen-inactivation technique for blood transfusions using this same photochemistry. Early in 2020, Goodrich and colleagues found that the riboflavin-UV light photochemical reaction that works for blood pathogen reduction also works on SARS-CoV-2, the virus that causes COVID-19. Their subsequent work to demonstrate the effectiveness of this process for human vaccine development has been supported by the National Institutes of Health. That process is now licensed as SolaVAX™ and exclusively licensed for human vaccine work by Solaris Vaccines, Inc.

DVM student Elizabeth Sullivan helping prepare the VacciRAPTOR for a test run with Zika virus solution.

Blood pathogens to coronaviruses

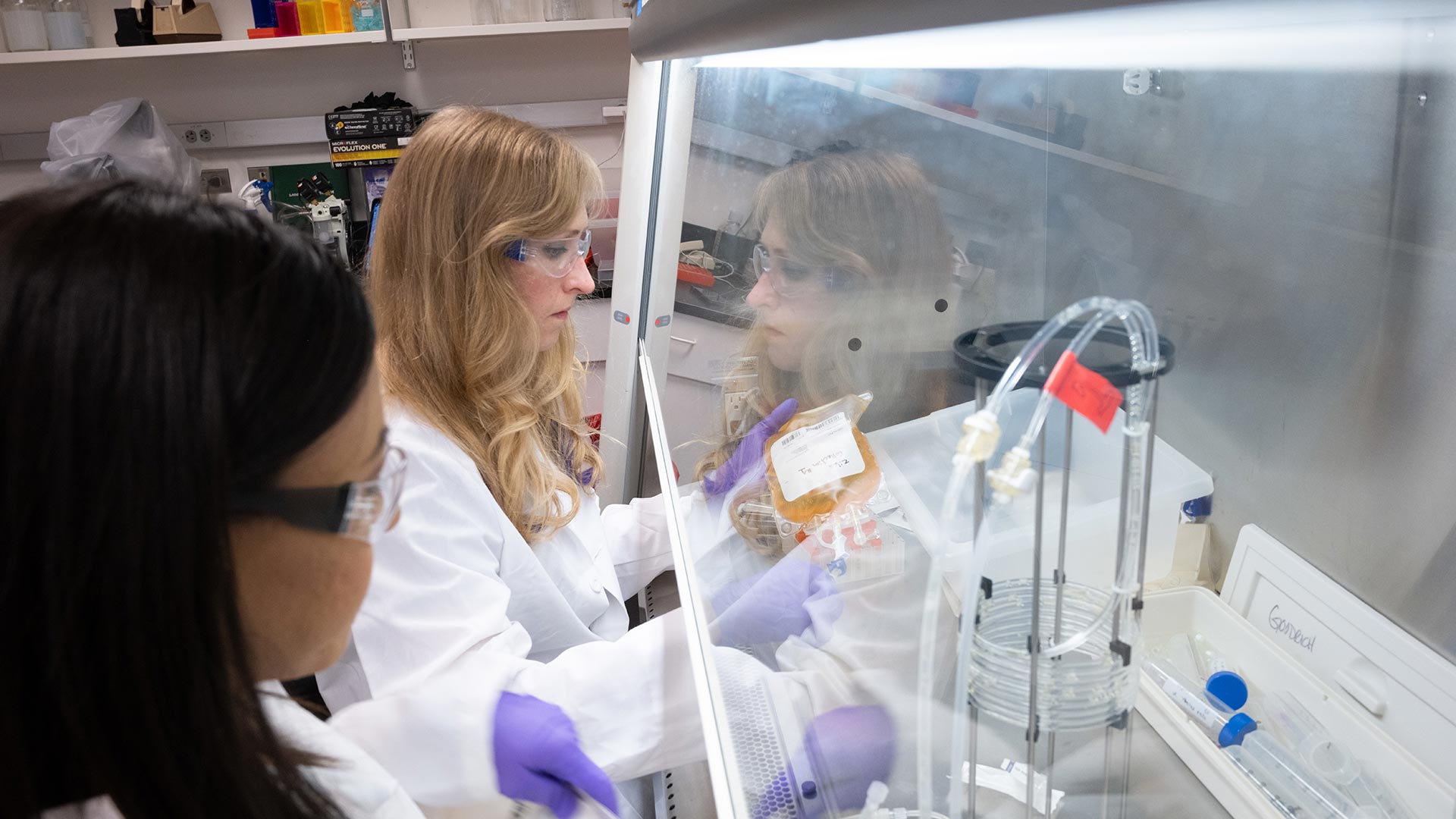

To test their SolaVAX™ vaccine development process, the infectious disease researchers had been using a modified version of a device commercially known as the Mirasol Pathogen Reduction Technology System, which Goodrich and colleagues invented over a decade ago. The Mirasol technology is owned by the medical device company Terumo BCT, where Goodrich spent part of his career. It is often used by blood banks to clear donated blood of viruses, bacteria and parasites. Blood is collected in clear plastic bags – familiar to anyone who’s donated blood – and then loaded into the Mirasol machine and exposed to UV light.

While this setup allowed the CSU vaccine researchers to prove the concept that the technology also works on coronaviruses, it was limited because only one bag of virus solution could be processed at a time, explained Lindsay Hartson, manager of the Goodrich laboratory at the Infectious Disease Research Center.

“It’s great for blood, but when we’re talking about scaling up to large-volume production for vaccines, it’s not a feasible or efficient model,” Hartson said.

Added Goodrich: “I think, early on, we recognized that this would work on a small scale and would certainly work to support things like early animal studies and toxicology work. But if we really wanted to be able to mass-produce vaccines, in an efficient and effective way, we were going to need to handle a lot more than, say, putting one bag at a time in the device and running it at a 600-milliliter volume and just repeating that over and over again.”

Enter the new VacciRAPTOR device. The engineers took the essential photochemical utility of the Mirasol device and reconfigured it to work faster and on larger volumes of virus solution. The device consists of a coil system through which the viral solution, pre-mixed with the riboflavin, is illuminated evenly by a circle of fluorescent lights at very specific wavelengths.

The SolaVAX™ process is rooted in a traditional vaccine technology – using an inactivated viral pathogen to stimulate an immune response – similar to how the influenza vaccine is made. But SolaVAX™ uses the safe, benign vitamin riboflavin, more commonly known as vitamin B2, in place of toxic chemicals like formalin, beta propiolactone or others that must be removed from the solution at the end of the process. In other words, explained Hartson, their method is a “gentler” but no less effective way of rendering pathogens inert while preserving the antigenic proteins that stimulate the desired immune response.

Engineering the device

The design of the VacciRAPTOR was inspired by a previous collaboration between Mizia and Goodrich in which they created a water-purification device using the same riboflavin-UV light chemistry.

The riboflavin-UV light process requires each unit volume of liquid to get illuminated evenly and consistently, said Mizia, explaining the engineering challenges of the project. “If you imagine you have a big light source and a big plate to try and do the entire surface area, and you’re flowing the liquid in, what if the corner here doesn’t get as much illumination as the center?” Mizia said. “The way to eliminate that problem was to have a fairly small passageway traverse through a homogenous light field. That’s how we came up with the coil idea.”

The original Mirasol blood pathogen reduction device treats approximately 30 milliliters (or one ounce) of liquid per minute. By comparison, the engineers’ new high-flowthrough device can inactivate about 1,000 milliliters (or one liter) of liquid per minute, according to Andraski, the master’s student in mechanical engineering who worked on the VacciRAPTOR with Mizia and Willman and is writing his thesis on the technology.

“We’re theorizing that this unit can eventually process in excess of 80 liters per hour, or something like 100,000 vaccine doses per hour,” Andraski said.

Pan-coronavirus vaccine, polio, influenza

Izabela Ragan, an assistant professor in the Department of Biomedical Sciences, serves on the team using the VacciRAPTOR to make and test vaccines, including a pan-coronavirus vaccine and one for Leishmaniasis. “The current plan is to use this new device for our research programs and to develop other inactivated vaccine candidates against parasites, bacteria and viruses,” Ragan said. “This device will help create the vaccine material needed for preclinical testing.”

What’s more, the VacciRAPTOR could inspire new ways of making vaccines for polio, influenza and other viruses more quickly, efficiently and safely, in areas of the world where access to vaccines remains a challenge, Goodrich added.

The collaboration on the VacciRAPTOR photochemical reactor received a boost from the Anschutz Foundation last year. The team won a portion of a $2 million gift to CSU that is funding projects aimed at preventing future pandemics. Mizia’s team at the Powerhouse Energy Campus is using that funding to continue refining the device’s design, including better thermal management and touchscreen user controls.

Goodrich reflected on the partnership with Mizia and the team that’s bringing CSU’s vaccine research capabilities to new heights.

“Innovation is really bringing together people with different talents and different skillsets to work on a problem,” Goodrich said. “You need people with an engineering background. You need people who know how to wire circuits and put light systems in place and design monitoring devices and flow systems. You need people who have the biology background as to how to grow the virus. None of this gets done without collaboration and cooperation such as we have here at CSU.”