In two minutes, learn about the team that came together to create a ventilator for rapid deployment.

See bottom of story for longer video.

Video and photos by Ron Bend.

A natural gas fuel injector may not be a staple in the medical device industry, but for a team of engineers from Colorado State University and Fort Collins-based Woodward, Inc., it proved to be a key component in the design of a low-cost, durable ventilator.

Back in early March, CSU and Woodward engaged in a joint effort to develop a ventilator that could be quickly manufactured and deployed if the state faced shortages. The project was a response to Colorado Gov. Jared Polis’ Innovation Task Force charged with developing rapidly deployable solutions to address the impacts of COVID-19.

In statewide remarks May 1, Polis gave a shout-out to the Woodward-CSU team’s efforts over the past several weeks.

“What a great example of Colorado innovation and ingenuity,” Polis said.

The new ventilator project, now in clinical testing stages, recently received further external validation and support: a $100,000 prize from the U.S. Army.

The XTech COVID-19 Ventilator Challenge was launched on April 5 by the Army Acquisition Executive with the goal to solicit the innovation community’s ideas for combatting the COVID-19 pandemic. With a prize pool totaling $1 million, applicants were asked to deliver white papers and virtual pitches describing their ideas, and concepts were judged based on their alignment with mission requirements, technical viability, regulatory aspects, and speed to production and deployment.

Looking for alternatives

Bryan Willson, executive director of CSU’s Energy Institute, was tapped to join a ventilator subteam as part of the governor’s task force back in March.

“We knew we had to look for alternatives to current supply chains, which were already being strained by the pandemic,” Willson said.

Willson contacted Tom Gendron, president and CEO of Woodward – known for its expertise in the manufacture and design of control systems for the aerospace and industrial sectors – to propose an idea: Could their off-the-shelf fuel injectors be modified to regulate the flow of oxygen for a ventilator?

“The Energy Institute has partnered with Woodward for years on different projects, and when I called Tom to suggest the idea of working together to build a ventilator, he was immediately on board,” Willson said.

Woodward had never manufactured a medical device before, let alone a ventilator that would need to be designed and produced over the course of weeks, not months or years. What they did have were the people and the expertise to develop a ventilator solution with the same precision and rigorous design process that the company is known for, Willson said.

Gendron and Doug Salter, Woodward’s vice president for corporate technology, recruited help from four of their business divisions to form a comprehensive team of engineers, programmers, designers and systems experts. The team also enlisted help from Ann Batchelor, assistant director of CSU’s Walter Scott, Jr. College of Engineering Department of Systems Engineering, and Dr. Heather Pidcoke, CSU’s chief medical research officer and associate director of research for the Translational Medicine Institute at CSU.

Woodward engineers Chris Burenheide, Rohit Vaidya and Dave Richards discuss the ventilator project.

“We wanted to move fast, but knew we had to make sure we stayed disciplined in our processes,” said Salter. “We first decided that there were four things that we wanted: Provide air to those in crisis; do no harm; ensure we’re not contributing to the spread of the virus; and tackle this project with a disciplined sense of urgency.”

The team worked around the clock, conducting extensive research on ventilator design and interviewing experts, including pulmonologists and respiratory therapists. to better understand ventilator functionality, use cases and requirements.

Just four days later, the first prototype ventilator design was ready for testing.

“We gathered a team at 8 a.m. at our technology lab in Windsor, Colorado,” Salter said. “We laid out a bunch of components and pieces on the tables, and by 8 p.m. the team had a working ventilator in a box.”

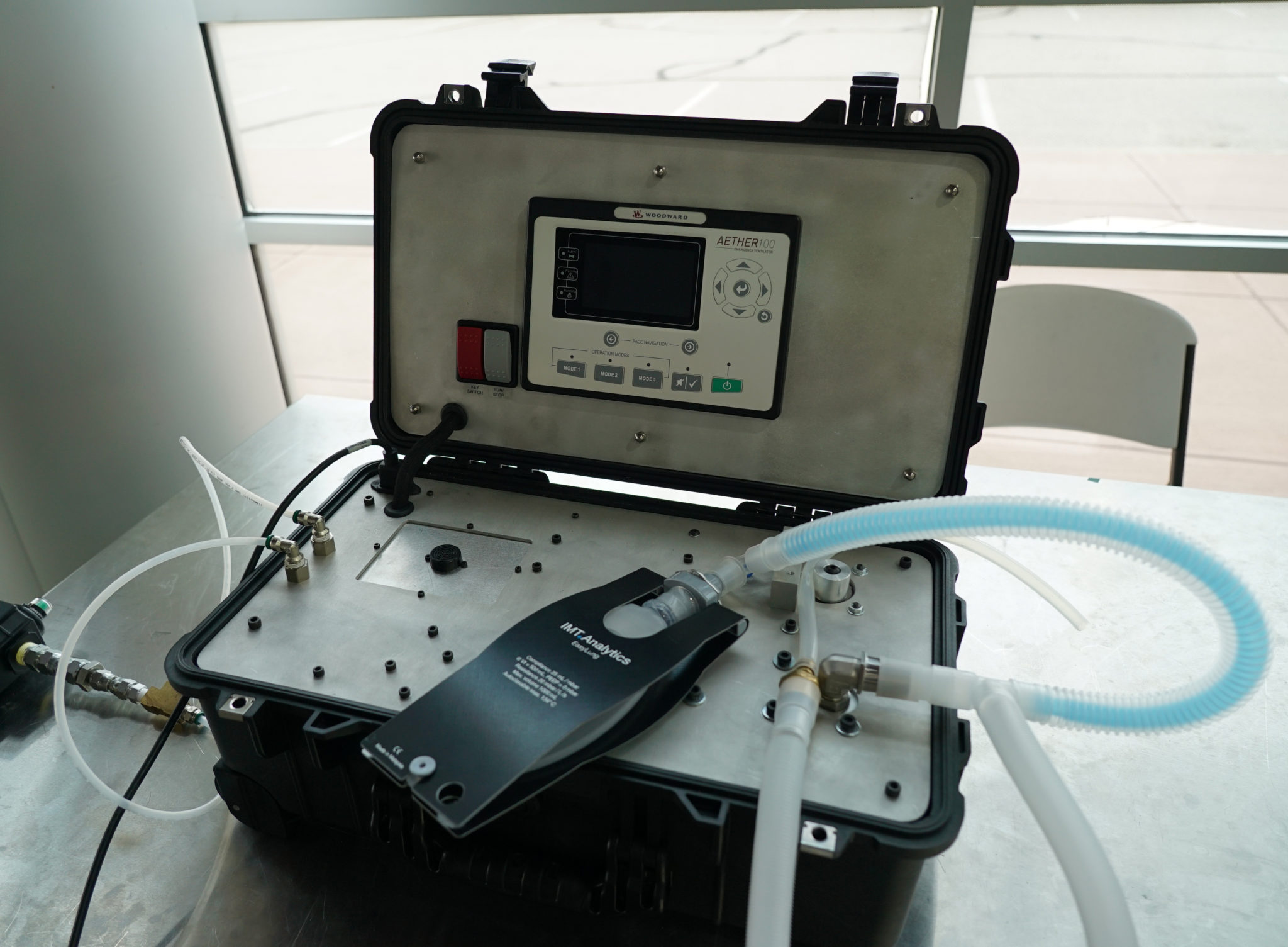

The Aether 100 ventilator, developed through a collaboration between Woodward and CSU.

Fine-tuning design

Since then, the ventilator – dubbed the Aether 100 – has undergone several iterations aimed at fine-tuning the controls, design, oxygen delivery, and human-machine interface before the first two pilot units go into production in early May.

“We’ve put this project into one of our aerospace facilities, which means that we have very firm traceability of all the components that go into it, control over materials, and control of the process to make sure that it’s assembled the same way every time,” Salter said. “We intentionally put it into an aerospace division because we felt like the idea of having to breathe for a patient is like flying an airplane – it has to work correctly every time.”

The pilot units will be tested side-by-side with commercial ventilators at Saint Joseph Hospital in Denver, Salter said.

The team is also focused on ensuring the long-term durability of the product. The Army XTech Challenge required a solution that was rugged enough for a field hospital, while having a small footprint. Aether 100 accomplishes both without losing any of its core functionality, and it is also designed to be quickly and cost-effectively scaled to production if a critical need arises.

Salter said they plan to continue with additional clinical testing to ensure efficacy and safety. This work will be done in partnership with the Anschutz Medical Center, and partial support has been received to fund the clinical trials.

“This is a team [of individuals] that had never worked together before this,” Salter said. “The CSU and Woodward interface has been spectacular, quite frankly. It never feels like we’re two organizations trying to fit together, we’re just one team trying to move this forward.”

The ventilator project was a true team effort. Get an in-depth look at the teams and processes that made it happen in this 8-minute video overview.

By Ron Bend